The twist drill bit is a fundamental tool used in many industries for creating precise holes in various materials. But how are these drill bits made? In this article, we will explore the fascinating production process of twist drill bits, from raw material selection to the final product. We’ll cover the key steps involved, including CNC grinding, the drill forging process, and heat treatment, while also discussing the importance of design and technology in manufacturing high-speed steel drill bits.

Before we dive into the production process, it’s essential to understand the basic design of a twist drill bit. These tools are characterized by their helical flutes that facilitate the removal of material as the bit cuts into the workpiece. The design must ensure durability, efficiency, and precision, which are crucial for high-speed steel drill bits.

Importance of Material Selection

The choice of material for a drill bit directly impacts its performance and durability. High-speed steel (HSS) is a popular choice due to its ability to withstand high temperatures and maintain sharpness over prolonged use. Manufacturers also consider factors like toughness and resistance to wear when selecting materials.

Drill Bit Manufacturing Steps

The production of a twist drill bit involves several meticulous steps. Let’s explore each stage to understand how these essential tools are crafted.

Step 1: Raw Material Preparation

The process begins with preparing the raw materials. High-speed steel rods are cut into lengths suitable for the desired drill bit size. These rods serve as the foundation for the subsequent manufacturing steps.

Step 2: The Drill Forging Process

Forging is a critical step that shapes the raw material into the basic form of a drill bit. In this stage, the steel rods are heated to a specific temperature to make them malleable. They are then placed into a die and hammered or pressed into the desired shape.

The forging process ensures that the steel structure is dense and aligned, which enhances the strength and durability of the drill bits.

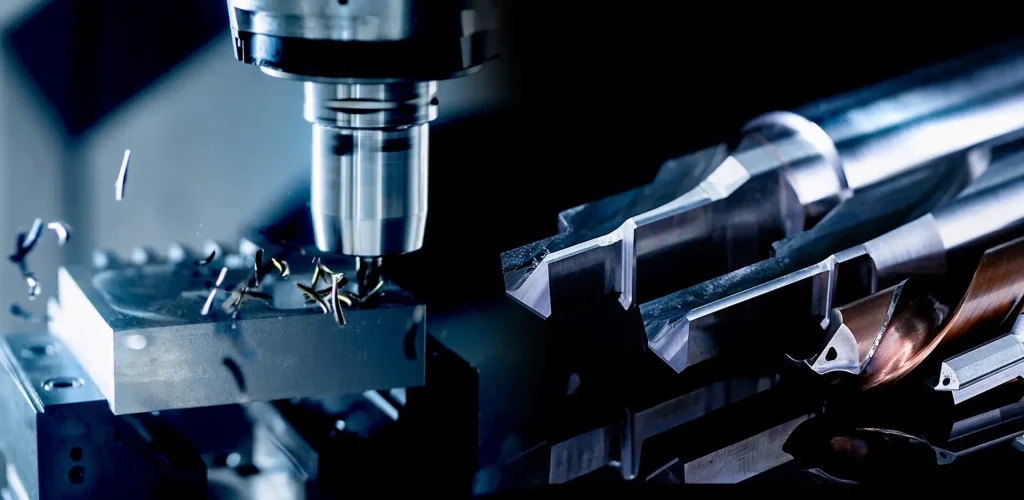

Step 3: CNC Grinding

Following forging, the rough drill blanks undergo CNC (Computer Numerical Control) grinding. This step involves using precision machines to grind the drill bit to its exact specifications. CNC grinding is crucial for achieving the correct cutting angles and ensuring uniformity across batches.

The high precision of CNC machines allows for consistent production of drill bits with minimal deviation, which is vital for maintaining quality and performance.

Step 4: Heat Treatment

Heat treatment is an essential phase that enhances the hardness and toughness of the drill bit. The bits are heated to a specific temperature and then rapidly cooled, a process known as quenching. This alters the microstructure of the steel, providing the necessary hardness for effective cutting.

After quenching, tempering is performed to relieve internal stresses and improve the toughness of the drill bit, preventing it from becoming too brittle.

Step 5: Surface Finishing

Once the drill bits have undergone heat treatment, they proceed to surface finishing. This step involves coating the bits with protective layers such as black oxide or titanium nitride to enhance their corrosion resistance and reduce friction during drilling.

Surface finishing also includes polishing the bits to remove any rough edges or burrs, ensuring a smooth surface that contributes to efficient drilling performance.

The Role of Technology in Drill Bit Production

The integration of advanced technology in drill bit production has revolutionized the manufacturing process. CNC grinding and automated heat treatment systems have significantly improved precision, consistency, and efficiency.

Moreover, technological advancements have enabled manufacturers to experiment with innovative drill bit designs and coatings, further enhancing performance and lifespan.

Innovations in Drill Bit Technology

Recent innovations in drill bit technology focus on improving cutting efficiency and extending tool life. For example, some manufacturers are experimenting with new coatings that reduce friction and enhance heat resistance. Others are exploring alternative materials that offer superior performance compared to traditional high-speed steel.

Quality Control in Twist Drill Bit Manufacturing

To ensure that each drill bit meets industry standards, rigorous quality control measures are implemented throughout the production process. Manufacturers conduct inspections at various stages to check for defects, dimensional accuracy, and overall performance.

State-of-the-art testing equipment is used to assess the hardness, toughness, and cutting efficiency of the drill bits, ensuring they meet the high demands of modern applications.

Conclusion

The twist drill bit production process is a complex yet fascinating journey that combines craftsmanship, precision engineering, and advanced technology. From the initial design phase to the final quality checks, each step is crucial in creating reliable tools that meet the needs of various industries.

By understanding the intricacies of drill bit manufacturing, you gain an appreciation for the meticulous effort involved in producing these indispensable tools. Whether you’re a professional machinist or a DIY enthusiast, knowing how your tools are made can enhance your appreciation of their value and performance.