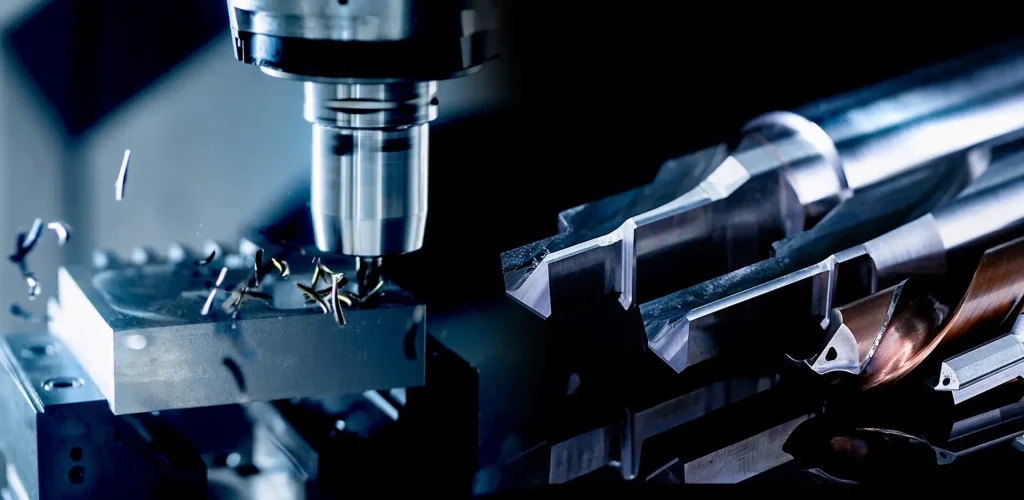

Drilling through hardened metal can be a daunting task, especially if you don’t have the right tools. The process requires precision and the appropriate drill bit to ensure effectiveness and prevent damage. If you’re wondering what type of drill bit to use for hardened metal, this guide will help you make an informed decision.

Choosing the right drill bit is crucial for drilling through hard materials. The most common types used for metal drilling include cobalt, carbide, high-speed steel (HSS), and titanium-coated bits. Each has unique properties, making them suitable for different metal hardness levels.

Cobalt Drill Bits

Cobalt drill bits are renowned for their ability to penetrate hard metals. These bits are made from high-speed steel with a percentage of cobalt added to enhance their heat resistance and durability. They’re perfect for drilling into stainless steel and other tough metals. Their heat resistance also means they can be used for prolonged periods without losing efficiency.

Carbide Drill Bits

If you’re looking for strength and endurance, carbide drill bits should be your go-to. These are made from a combination of carbon and tungsten, resulting in a bit that’s incredibly hard and heat-resistant. Carbide bits are suitable for industrial drilling tasks and can handle the toughest materials. However, they are more brittle and can break if not used properly, so caution is advised.

High-Speed Steel (HSS) Drill Bits

HSS drill bits are a more affordable option for metal drilling. They are versatile and can handle a variety of materials, including some hardened metals. While they lack the durability of cobalt or carbide bits, they are perfect for less demanding tasks and are a staple in many toolkits.

Titanium-Coated Drill Bits

Titanium-coated bits offer a balance between performance and cost. They are essentially high-speed steel bits with a titanium nitride coating, which increases their hardness and reduces friction. These bits are ideal for drilling through metal sheets and can last longer than standard HSS bits. However, once the titanium coating wears off, their performance diminishes.

Choosing the Right Drill Bit

When selecting a drill bit for hardened metal, consider the material’s hardness and the drill bit’s properties. For frequent and heavy-duty tasks, cobalt and carbide bits are recommended. For occasional use or less demanding projects, titanium-coated and HSS bits can suffice.

Conclusion

Drilling through hardened metal requires patience, precision, and the right tools. By choosing the appropriate drill bit type, you can ensure efficiency and prolong the life of your equipment. Whether you’re a professional or a DIY enthusiast, investing in the right drill bits will save you time and effort. Always remember to follow safety precautions when drilling, and let the bit do the work for you.