When it comes to drilling hard metals, the material of the drill bit is crucial. Different materials offer varying levels of durability, heat resistance, and cutting ability. The choice of material can affect not only the ease of drilling but also the lifespan of the bit and the quality of the work. Here are the most common materials used in drill bits for metal, each offering unique benefits and considerations:

High-Speed Steel (HSS)

HSS drill bits are a popular choice for many metalworking projects due to their affordability and versatility. They are a go-to option for general-purpose drilling and are readily available in most hardware stores. These bits can handle softer metals and are often coated to improve performance, which makes them suitable for a wide range of applications. However, for extremely hard metals, you might need something more robust, as HSS bits may not withstand the increased heat and stress.

Cobalt Drill Bits

Cobalt drill bits are made from an alloy that includes cobalt, which increases heat resistance and hardness. They are excellent for drilling into hard materials like stainless steel and cast iron, providing a reliable performance where other bits may fail. Cobalt bits retain their sharpness longer than standard HSS bits, making them a cost-effective choice for heavy-duty applications. Their resilience against high temperatures means they are less likely to dull quickly, saving time and money in the long run.

Carbide Drill Bits

Carbide drill bits are the hardest and most durable of the options available. Made from carbide, a compound of carbon and another metal, these bits can cut through even the toughest metals with ease. They are ideal for industrial applications where precision and durability are paramount, offering unparalleled performance in demanding environments. While more expensive, their longevity and effectiveness in cutting through hard metals make them a valuable investment for professionals and serious hobbyists alike.

Coated Drill Bits

Many drill bits are coated with materials such as titanium nitride or black oxide to enhance their performance. Coatings can increase a bit’s lifespan by improving heat resistance and reducing friction, which is particularly beneficial when drilling into tough materials. However, the coating can wear off over time, so it’s essential to consider the base material’s quality to ensure continued effectiveness. The right combination of coating and material can significantly extend the life of the drill bit and improve overall results.

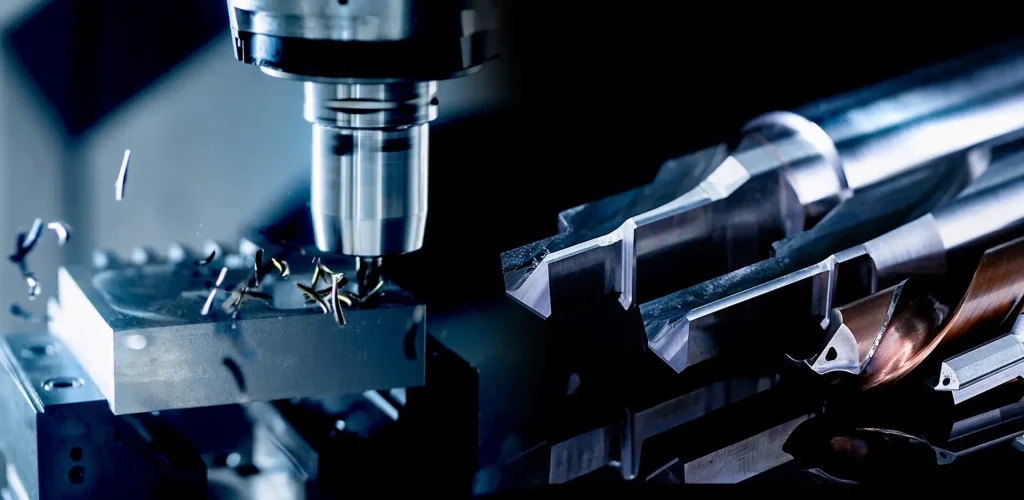

Types of Drill Bits for Hard Metals

Now that we know about the materials, let’s look at the different types of drill bits designed for hard metals. The shape and design of the bit play a critical role in determining its suitability for specific tasks. Understanding these differences can help you select the right tool for your project needs:

Twist Drill Bits

These are the most common types of drill bits and are available in various materials and coatings. Twist drill bits are versatile and can be used for a wide range of drilling tasks, including hard metals, when made from cobalt or carbide. Their spiral design allows for efficient cutting and chip removal, which is crucial when working with hard materials. With the right material and coating, twist bits can handle a multitude of challenges, making them a staple in any toolkit.

Step Drill Bits

Step drill bits are cone-shaped and can drill multiple hole sizes. They are excellent for drilling thin sheets of metal and provide smooth, clean holes without burrs, making them ideal for tasks that require precision and a neat finish. The stepped design allows for gradual drilling, reducing the risk of bit breakage and ensuring a smoother operation. While they are not suitable for all metal thicknesses, their unique design offers flexibility and efficiency for specific applications.

Spade Drill Bits

While primarily used for wood, spade bits can be adapted for metal with the right coating and material. They are not ideal for precision work on hard metal, but can be useful for larger holes where exact measurements are not critical. The wide, flat blade of a spade bit allows for rapid material removal, which can be advantageous in certain situations. However, care must be taken to ensure the bit is suitable for the metal type to avoid damage or wear.

Auger Drill Bits

Designed for deep holes, auger bits are typically used in wood but can be modified for metal with the right material. They provide excellent chip removal, which can be beneficial when drilling deep into hard metals, helping to prevent overheating and bit binding. While not as common for metalworking, when adapted correctly, auger bits can be a valuable tool in specific scenarios where depth and chip management are priorities.

Choosing the Right Drill Bit

Selecting the right drill bit for hard metal requires consideration of several factors. The complexity of the task and the specific requirements will dictate the most appropriate choice. Here are some key considerations to keep in mind:

Material and Coating

For most hard metals, cobalt and carbide drill bits are the best choices due to their durability and heat resistance. These materials are designed to withstand the intense conditions encountered when drilling hard metals. If you’re on a budget, consider HSS bits with a titanium coating, which can offer improved performance at a lower cost. The coating enhances the bit’s longevity and efficiency, making it a practical option for less demanding tasks.

Size and Shape

The size and shape of the drill bit should match the specific requirements of your project. For precision work, twist and step bits are ideal, offering control and accuracy. For larger holes, consider spade or auger bits if they are available in the necessary material, as they can provide the necessary power and efficiency. Matching the bit to the task ensures better results and reduces the risk of tool damage or workpiece imperfections.

Drill Speed

Hard metals require slower drill speeds to prevent overheating and prolong the life of the drill bit. Using the correct speed is crucial for maintaining bit integrity and achieving clean, precise holes. Ensure your drill has adjustable speed settings and use cutting fluid to reduce friction, further extending the life of your drill bit and improving the quality of your work.

Tips for Drilling Hard Metals

Here are some tips to ensure a successful drilling experience. Proper technique and preparation can significantly enhance the outcome and safety of your project:

- Use Cutting Fluid: Apply cutting fluid to reduce heat and friction. This not only extends the life of the drill bit but also improves the quality of the hole, ensuring a smooth finish and reducing the risk of bit damage.

- Secure the Workpiece: Always clamp the metal securely to prevent movement during drilling. This ensures accuracy and reduces the risk of accidents, providing a stable work environment and minimizing potential errors.

- Start with a Pilot Hole: Drill a small pilot hole first to guide the larger drill bit. This helps maintain accuracy and reduces stress on the drill bit, facilitating a smoother drilling process and improving final results.

- Apply Consistent Pressure: Use steady, consistent pressure when drilling. Avoid forcing the drill bit, as this can lead to breakage or damage to the workpiece, compromising both the tool and the project.

- Regularly Withdraw the Bit: Periodically pull the drill bit out of the hole to clear away metal shavings and reduce heat build-up. This practice helps maintain bit sharpness and prevents overheating, preserving the tool’s effectiveness.

Conclusion

Choosing the right drill bit for hard metal is crucial for both the success of your project and the longevity of your tools. By understanding the materials and types of drill bits available, you can make an informed decision that suits your specific needs. Remember to consider factors like material, size, and drill speed, and follow best practices to ensure a safe and efficient drilling process. With the right tools and techniques, even the toughest metals can be drilled with precision and ease, transforming challenging tasks into manageable projects.